Necessity of electrolyzation:

Electrolyzation generates 2 kinds of functional water,one is alkalin water, and the other is acidic water.Alkaline water is quite effective to cleaning and degreasing, and acidic water is effective to disinfection.

The purpsose to use dtergent is to remooe a dirt and oil with surface active agent, but surface active agent is chemical and harmful for human body and the cause of serious environmental problem(o-dissolution for long time),and after using that chemical,rinse with a plenty of water is necessary.as a result, to stop or decrease of chemical detergent is strongly requested as world concerns now.

Under such circumstances,Alkaline electrolyzed water is now in the limelight as new condept technology, and our KDS machine has been designed and developed to satisfy all requirement in cleaning industry,environmental safety and viewing from human health issue etc.

SPECIALITY OF OUR KDS ELECTROLYZED MACHINE:

Our KDN machine stable produces only alkalie water at pH13.2 or more,but no acidic water,though ordinal electrolyzation generates both alkaline and acidic water at same time(acidic water has wasting trouble).pH13 is quite high alkaline level and shows effective cleaning power,also excellent anti-rust effect,strong disinfection power though water is like plane water

Our machine generation process:

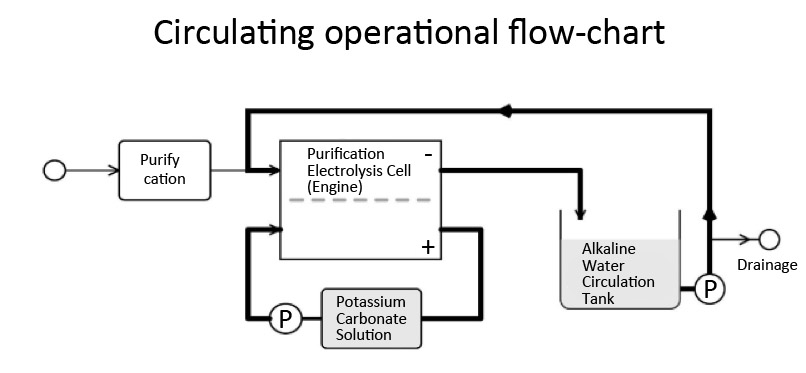

(1)City tap water>(2)Sortener>(3)Activated carbon(Hybrid filter)>(4)RO Filter(for Pure water)>(5)Special circulating electrolyzing generation

After finished treatment progress to omit hard ingredient and unpurity in the above(1)-(5),Special alkali electrolyzed water is produced with cleaning effect and disinfection effect by circular Electrolyzed Generation in special electrolyzed machine.

Our product is totally different from other suppliers,simply adding alkali salt in water and electrolyzing with alkali solution,promoting as “Electrolyzed water”.

This water is product,having high risk in operational environment with increase of residual,although searching after discrimination of products in keen pH competition.

Our electrolyzed water is highest cleaning water,generated in circulating electrolyzed water(H2O)6:BLI TECHNOS Alkaline Electrolyzed Water Unit KDN…Standard accessories and check points vefore installation.

Metal-work with water,it`s dream come true.

The special alkaline electrolysis water has been developed to cut down of CO2,improve working environment and reduce environmental load by not oil and chemical power at metal processing site.

This special alkaline electrolysis water is much more safety than conventional metalworking grease ad oil,and can decrease solvent and chemicals,because the raw material is water only,so it can solve the all problem with this special water in the process of metalworking.

・This special water prevents corrosion and rust.

・Safety processing

・Improvement by clean working environment.

| The voice from our customer

No fume,no bad smell,better working environment. |